Carbon Steel

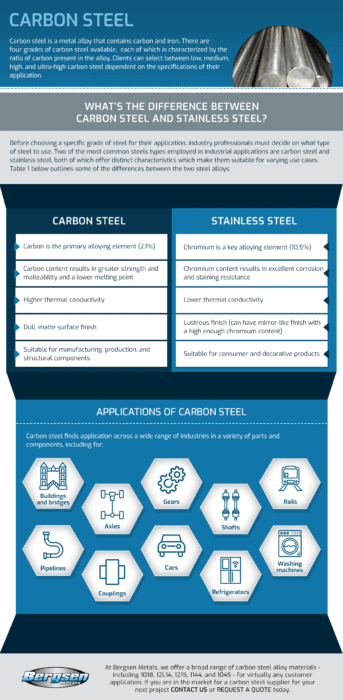

Carbon steel is a metal alloy that contains carbon and iron. There are four grades of carbon steel available, each of which is characterized by the ratio of carbon present in the alloy. Clients can select between low, medium, high, and ultra-high carbon steel dependent on the specifications of their application.

What’s the Difference Between Carbon Steel and Stainless Steel?

Carbon Steel Grades and Properties

Selecting the proper carbon steel grade is often critical to a project’s success. However, choosing the right grade requires an understanding of the types available and their individual characteristics. Below, we’ve outlined some of the common carbon steel grades and their properties to facilitate our customers’ decision-making processes.

Before choosing a specific grade of steel for their application, industry professionals must decide on what type of steel to use. Two of the most common steels types employed in industrial applications are carbon steel and stainless steel, both of which offer distinct characteristics which make them suitable for varying use cases. Table 1 below outlines some of the differences between the two steel alloys.

| Carbon Steel | Stainless Steel |

|---|---|

|

|

4140 Steel

Learn more about 4140 Cold-Finished Annealed Steel

4140 steel is a low-alloy steel that contains both chromium, manganese, and molybdenum. This alloy is widely considered to be one of the more versatile options when it comes to carbon steel and is commonly utilized for industrial forgings, such as the oil and gas sector. It’s readily machinable and offers exceptional toughness, ductility, and hardenability.

1018

Learn more about C1018 Cold Drawn Steel

1018 steel is a low-carbon steel alloy that demonstrates excellent weldability and machinability. Similar to 4140 steel, it’s commonly utilized for forged machinery parts and shaft components (e.g., motor, hydraulic, and pump shafts). Generally, this alloy does not undergo hardening or tempering, as most of these treatments are ineffective.

12L14

12L14 steel contains between 97.91–98.7% iron with 0.15–0.35% lead. The addition of lead results in greater machinability, as well as decreased strength. Typical applications for this steel include aircraft components, such as landing bolts, fasteners, bushings, and shafts.

1215

Although 1215 steel is not as affordable as other grades of carbon steel, it allows for higher machining efficiency and speed, which results in lower production costs. The additions of phosphorous and sulfur to the material lend the steel alloy excellent chip breaking properties.

1144 Steel (Stressproof®)

Stressproof® 1144 steel is a proprietary steel alloy produced by Niagara LaSalle. It exceeds numerous industry quality standards and offers a variety of advantageous characteristics, including:

- Fatigue and stress resistance

- Superb machinability

- Minimal warping and distortion

- Natural strength without heat treatment

- Superior surface quality

This alloy is used in a wide range of industrial applications, including for the manufacture of machine components such as arbors, bushings gears, pinions, rods, shafts, and sleeves.

1045 Steel (Turned, Ground, and Polished)

Learn More about 1045 Cold Drawn Steel Bar

1045 steel is a medium-carbon steel alloy that exhibits greater material strength than 1018 steel due to its higher carbon content. This alloy is primarily used for applications that require exceptional strength, such as machine parts (e.g., bolts, gears, pinions, and shafts).

1045 steel often undergoes turning operations to create turned, ground, and polished shafting. This process—in contrast to cold drawing—minimizes the risk of warping or distortion due to internal stresses. Although this alloy demonstrates poor weldability, it does respond well to heat treatment.

Applications of Carbon Steel

Carbon steel finds application across a wide range of industries in a variety of parts and components, including for:

- Buildings and bridges

- Axles

- Gears

- Shafts

- Rails

- Pipelines

- Couplings

- Cars

- Refrigerators

- Washing machines

Contact Bergsen Metals for Your Carbon Steel Needs

At Bergsen Metals, we offer a broad range of carbon steel alloy materials—including 1018, 12L14, 1215, 1144, and 1045—for virtually any customer application. If you are in the market for a carbon steel supplier for your next project, contact us or request a quote today.